Marc Baumgardner, PhD

Exhaust Gas Catalyst

**This is an on-going project with collaborators at Colorado State University**

Poison Build-up and Performance Degradation of an Oxidation Catalyst in 2-Stroke Natural Gas Engine Exhaust

Poison Build-up and Performance Degradation of an Oxidation Catalyst in 2-Stroke Natural Gas Engine Exhaust

Marc E.Baumgardner (Gonzaga University) and Daniel B. Olsen (Colorado State University)

--------------

--------------

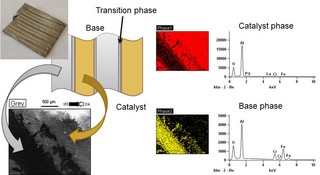

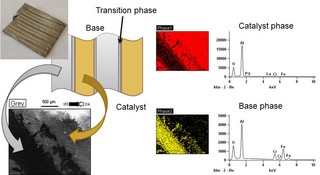

Due to current and future exhaust emissions regulations, oxidation catalysts are increasingly being added to the exhaust streams of large-bore, 2-stroke, natural gas engines. Such catalysts have been found to have a limited operational lifetime, primarily due to chemical (i.e. catalyst poisoning) and mechanical fouling resulting from the carry-over of lubrication oil from the cylinders. It is critical for users and catalyst developers to understand the nature and rate of catalyst deactivation under these circumstances. This study examines the degradation of an exhaust oxidation catalyst on a large-bore, 2-stroke, lean-burn, natural gas field engine over the course of 2 years. Specifically this work examines the process by which the catalyst was aged and tested and presents a timeline of catalyst degradation under commercially relevant circumstances. The catalyst was aged in the field for 2 month intervals in the exhaust slipstream of a GMVH-12 engine and intermittently brought back to the Colorado State Engines and Energy Conversion Laboratory for both engine testing and catalyst surface analysis. Engine testing consisted of measuring catalyst reduction efficiency as a function of temperature as well as the determination of the light-off temperature for several exhaust components. The catalyst surface was analyzed via SEM/EDS and XPS techniques to examine the location and rate of poison deposition. After 2 years on-line the catalyst light-off temperature had increased ~55°F and ~25 atomic% poisons (S, P, Zn) were built up on the catalyst surface, both of which represent significant catalyst deactivation.

The next phase of this project will be to regenerate the catalyst via washing and then to repeat the degradation study.